Reference Designation System for Power Plants

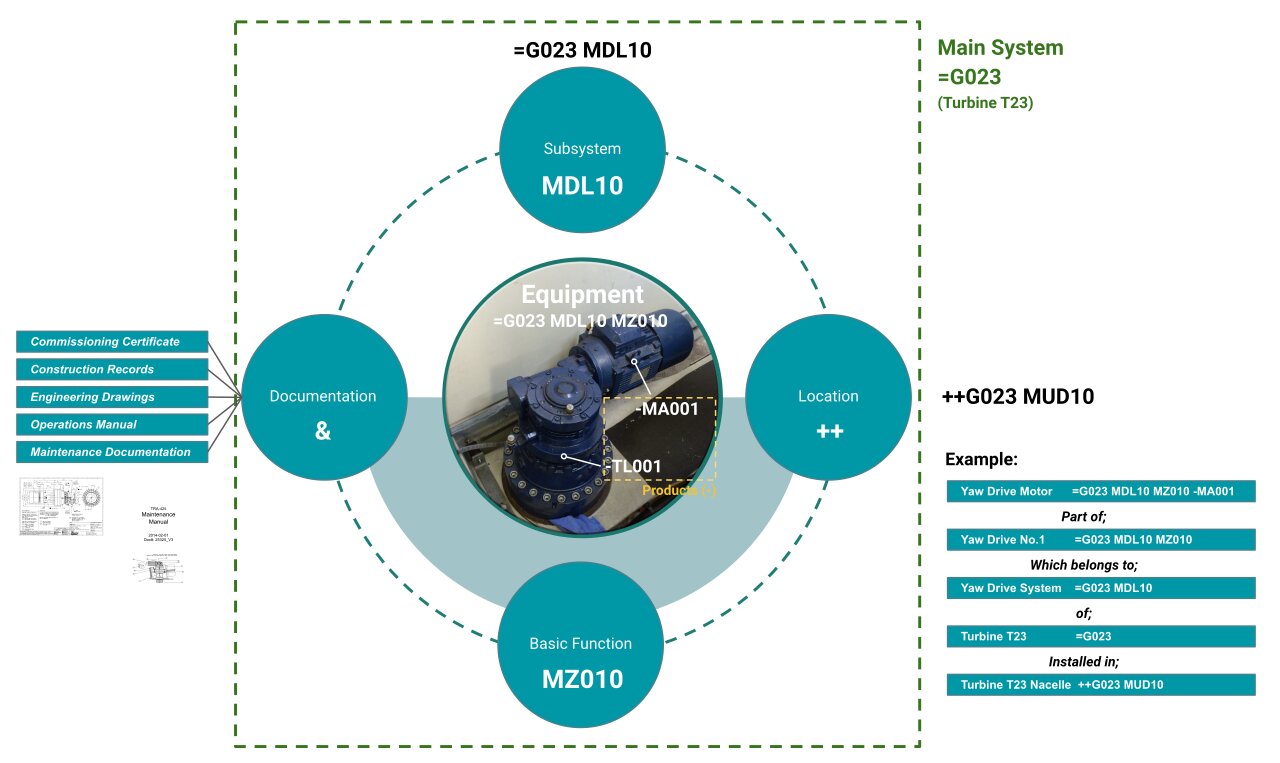

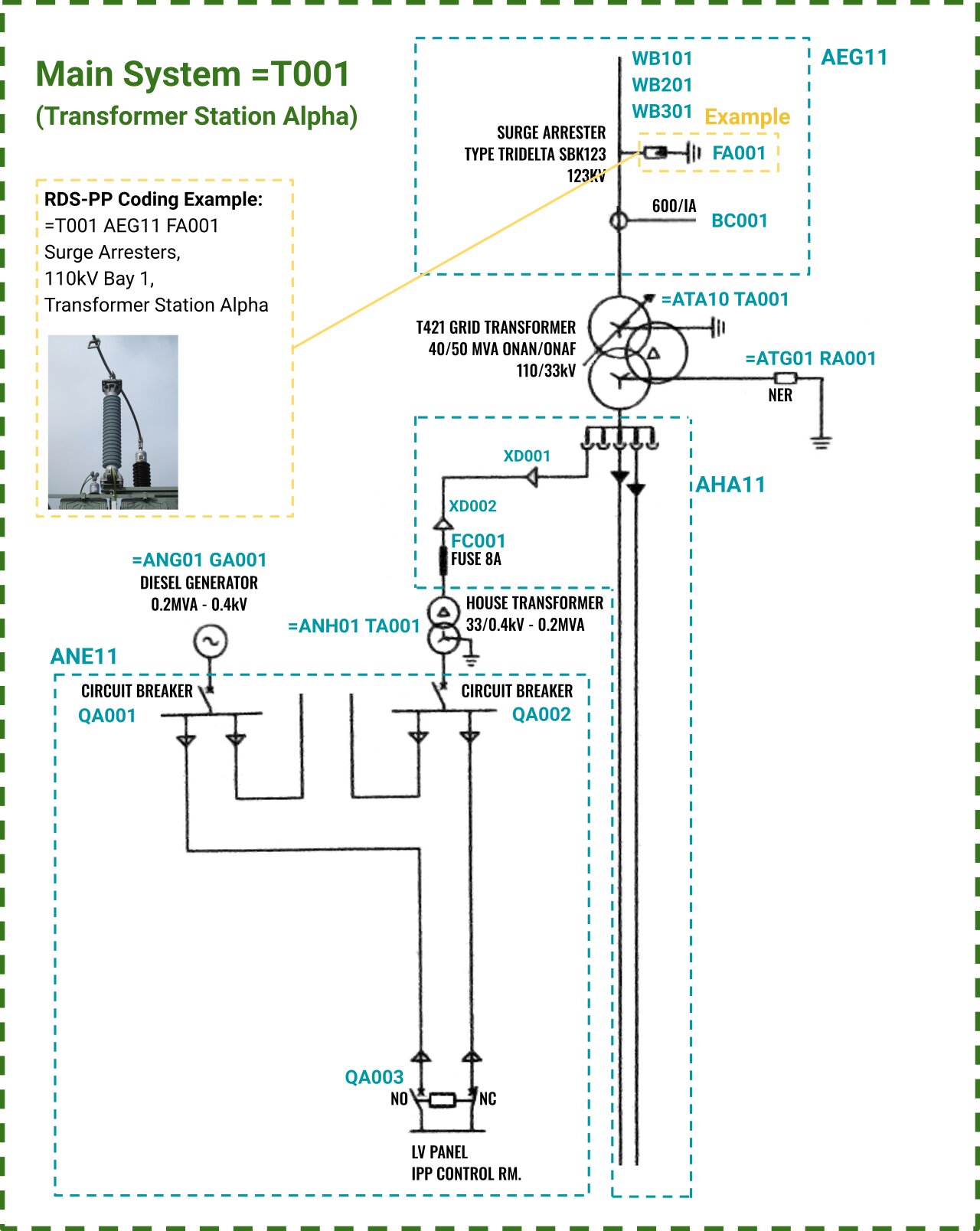

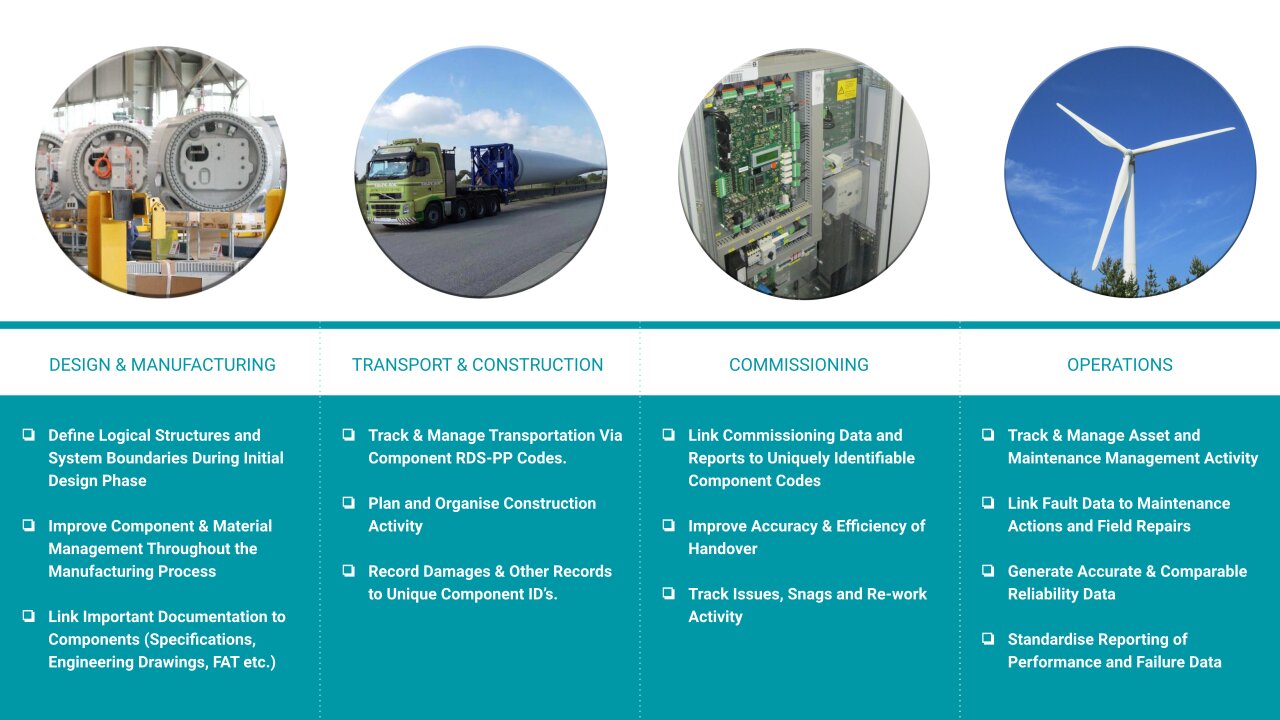

RDS-PP (Reference Designation System for Power Plants) coding and structures allow your organisation to manage and compare equipment and information throughout the lifecycle of your assets. Mech-V has long-term experience in the application of RDS-PP coding for new and existing wind energy projects both On-shore and Off-shore. We provide consultancy services to clients undergoing asset data management projects and assist them in the implementation of RDS-PP for their renewable assets.