- Home

- ServicesOur Services

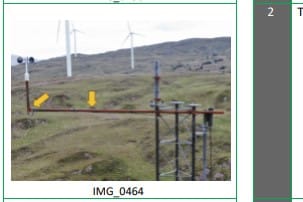

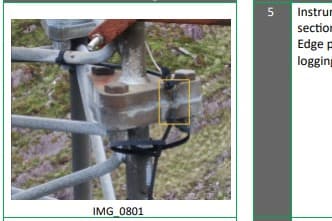

Field Services

- Walkdown Inspections

- Wind Turbine Blade Inspections

- Gearbox Inspections

- Equipment Receiving / Component Inspection

- Met Mast Inspections

- Emergency Call Out Service

- Due Diligence Inspections

- Pre-Takeover Inspections

- End-Of-Warranty Inspections

- Life Extension Inspections

- Oil And Grease Analysis

- Non Destructive Testing

- Insurance Inspections

- Resources

- AboutAbout

- Contact

- Home

- ServicesOur Services

Field Services

- Walkdown Inspections

- Wind Turbine Blade Inspections

- Gearbox Inspections

- Equipment Receiving / Component Inspection

- Met Mast Inspections

- Emergency Call Out Service

- Due Diligence Inspections

- Pre-Takeover Inspections

- End-Of-Warranty Inspections

- Life Extension Inspections

- Oil And Grease Analysis

- Non Destructive Testing

- Insurance Inspections

- Resources

- AboutAbout

- Contact